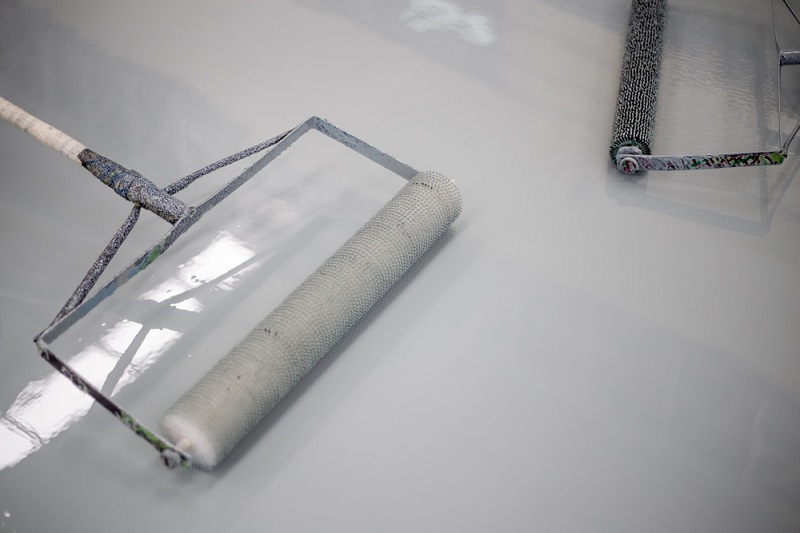

The industrial epoxy flooring coating has turned to become one of the most effective flooring used in different sectors of constructions. Commercial, residential or offices are using the floorings for the extra ordinary appearances and durability

The industrial epoxy floor coating helps to safeguard the concrete structure underneath from any sort of cracks, grease, moisture or even stains. These coating is quite durable and also very safe for the hard floors. The biggest benefits of the industrial epoxy floor coating is that it is resistance of slip, resistant of shock, and also the rate of vexing is very less as compared to concrete or other types of industrial flooring.

Which material is cheaper- Tile or the Epoxy?

When we compare both the materials then the thing that can be concluded is that the cheaper material is the industrial epoxy floor coating in compared with the tiles. In some of the surveys we see that the floor tiles almost run and are placed for about $3 to $5 per square of the floor. On the other hand the industrial epoxy floor coating will cost us around $3 to $7 per square foot. There are many different types of tiles like the garage tiles which may cost for about $2 to $24. The charges may be less for installing this which is as less of 1$. On the other hand the installation of epoxy materials cost $1 to $2 per square foot, and it also involve the labor costs that is around $2 to $5 per square foot on damage.

Where are the industrial epoxy floor coating used?

These materials are extremely tough to be used. It helps to resist the water and also protects the floors from any sort of spills and also slipping of anyone. These materials include chemicals that are harsh in nature and can harm the other floor coatings.

It is very important to regularly sweep the entire floor so that it does not get dirty very fast. It can also include vacuuming the entire area for the safety purpose. The mob must be dipped in hot water and then the epoxy coating will completely shine and may look new.

What are some of the disadvantages of the industrial epoxy floor coating?

There are a few disadvantages of the industrial epoxy floor coating.

Firstly, the levels of moisture in the floor can affect the lasting capacity of an epoxy product. The moisture may form due to water accumulation on the floor, if not dried may lead to floor damages Any molecules of moisture trapped under the surface can be a problem as it gets evaporating. To remember, it is very important to properly maintain it and taken care of it. These materials usually require low maintenance and it doesn’t get damaged very easily like the other flooring options. Basically, the epoxy flooring lasts for about 2 to 3 years depending upon the pressure and placement on the floor, if not maintained properly

Which one is better- Epoxy or the polyester resin?

Polyester is also another good adhesive material but not as good as the industrial epoxy floor coatings. On the other hand it is around 20 percent weaker than the other bonds made by industrial epoxy floor coatings. This basically makes epoxy resin the best choice in terms for fiberglass repair work. When we talk about the strongest bond forming then both epoxy and resin can be strong but epoxy is definitely the stronger one. The main difference between these two is the drying times it takes. Both of these require good mixture before use, but here, epoxy hardens much faster than resin glue.